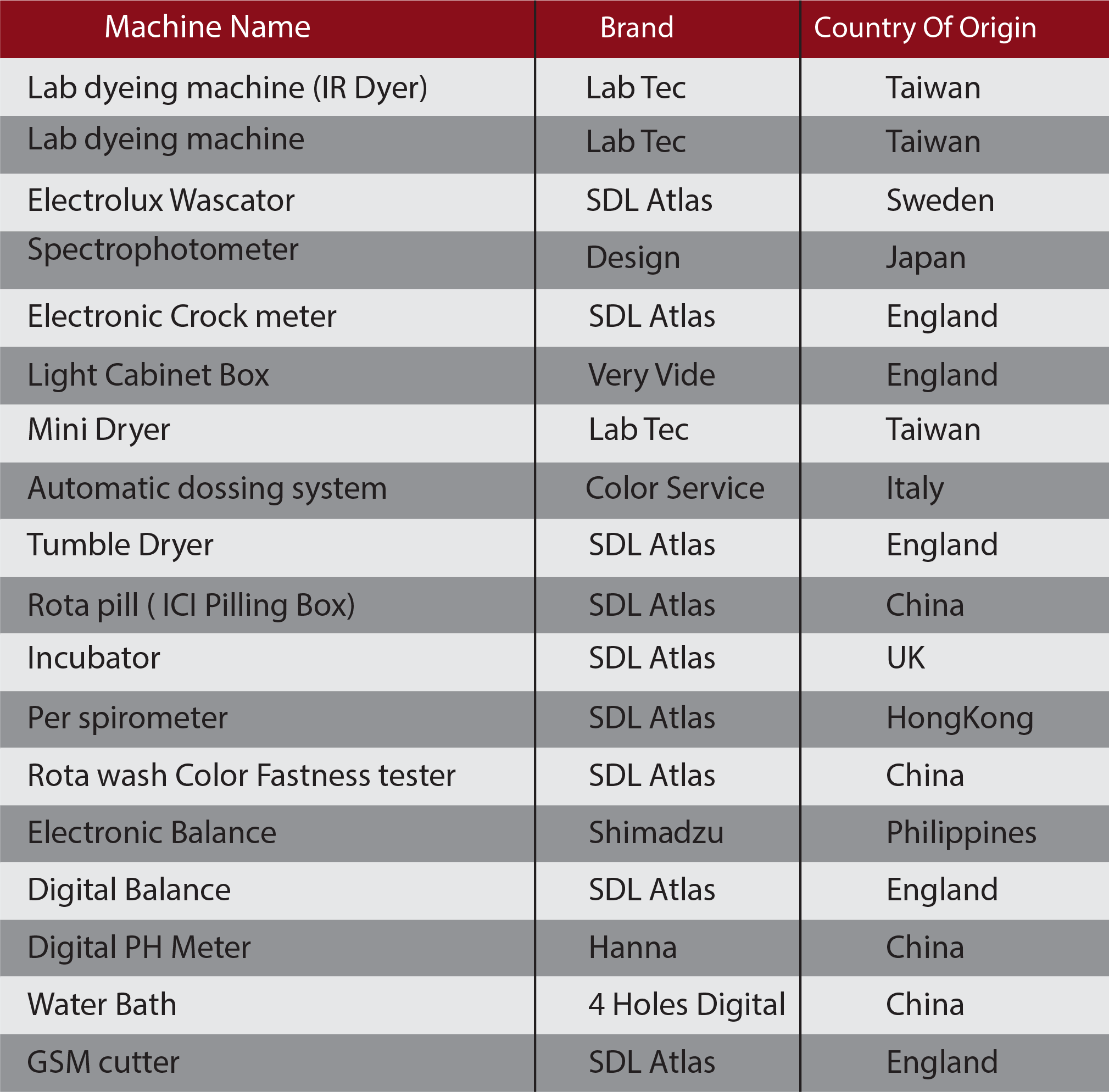

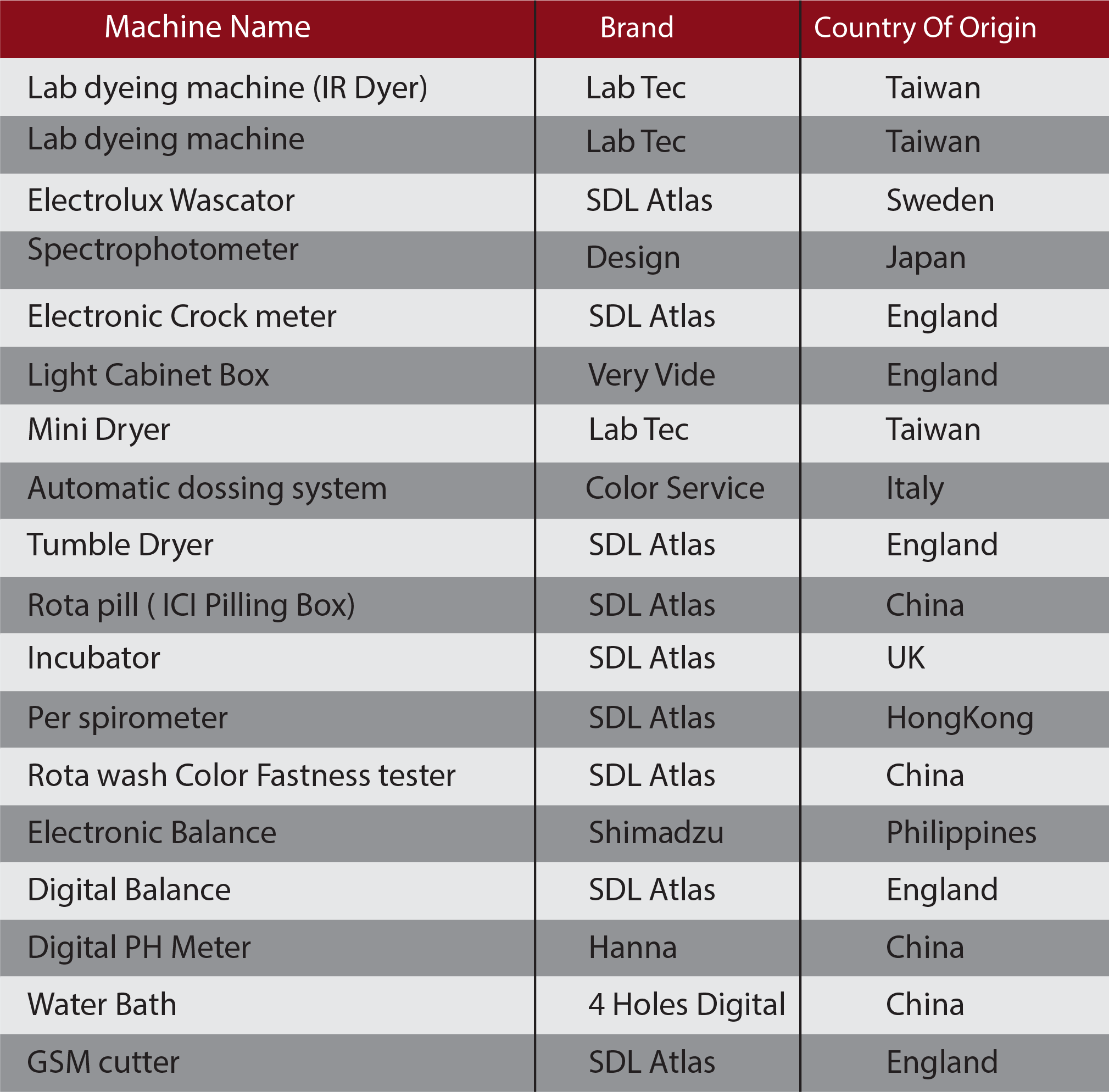

Dyeing Lab Machine Criteria

The knitted fabric is dyed using state of the art machines & technology. Right now, we are capable of produces 40 Ton of dyed fabric each day. Machine capacity in individual 1500kg 2 set, 1250kg 1 set, 1200kg 1 set, 1000kg 3 set, 750kg 5 set, 500kg 6 set, 250kg 2 set, 150kg 1 set, sample capacity 50kg 1 set, 25kg 3 set, 15kg 2 set, 10kg 2 set. Lawer auto-dispensing system controls & distributes all dyes, chemicals, salt & soda. Branded finishing machines & Quality Control Laboratory produces perfect quality fabric each time.

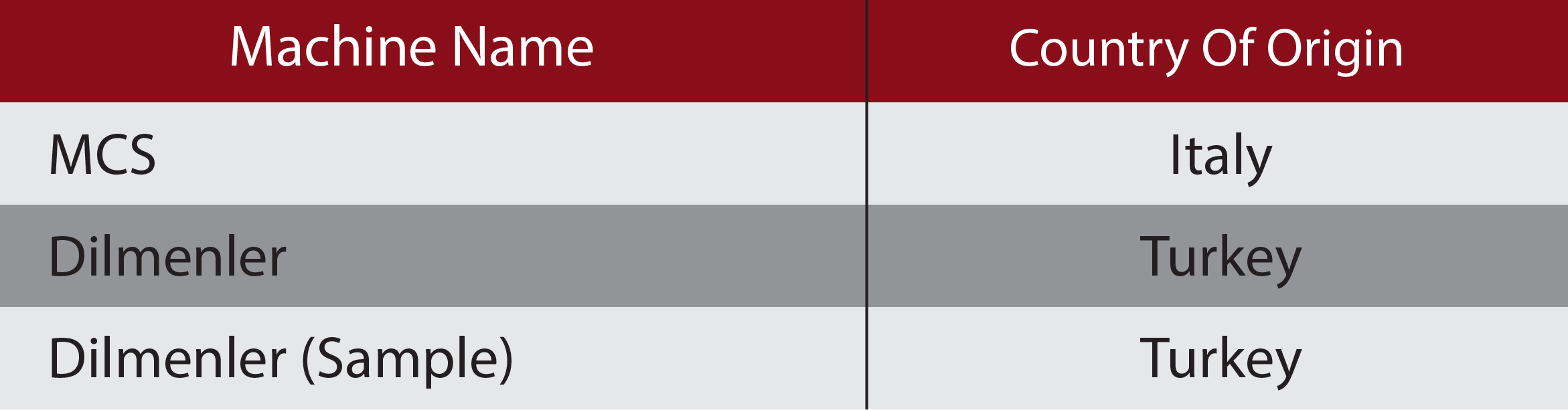

We have 40-ton/ day Finishing capacity for dyed fabric. In open width line, dyed fabric is being slitted to open by auto slitting/squeezing machine. Then for distortion detection and correction, the Stenter machine is used, which is equipped with Mahlo RMS branded Weft straighteners. Lastly, we complete the Finishing process by using the compacting machine. A bit different process is used for finishing Tubular Fabric. At first, fabric goes to the tubular squeezing machine, then goes to the steam drying machine, and finally compacting machine for better control of shrinkage and GSM. For Raising/napping, for complete range of accessories for woven and knitted fabrics that are suitable for open width and/or tubular fabrics, which have working width from 1,800 mm to 3,600 mm.